A Look Inside Dairy Processing Plants with Neologic Engineers

At Neologic Engineers, we understand

that the heart of a successful dairy

processing plant lies in its equipment. From the initial intake of raw milk

to the final packaged product, every stage demands precision, efficiency, and

unwavering hygiene standards. We take pride in providing cutting-edge equipment

solutions that empower dairy businesses to thrive.

Partnering for Success: We

view ourselves not just as manufacturers, but as partners in our clients'

success. We work closely with dairy processors to understand their unique needs

and challenges. Whether it's a small-scale operation specializing in artisanal

cheese or a large-scale facility producing a variety of dairy products, we

offer tailored solutions to optimize every step of the process.

Optimizing Each Stage of

Processing:

Reception and Storage: Our

milk receiving tanks and silos are designed for optimal hygiene and temperature

control, ensuring the quality of raw milk. Efficient pumping systems and

filtration units further guarantee a clean and pure base product.

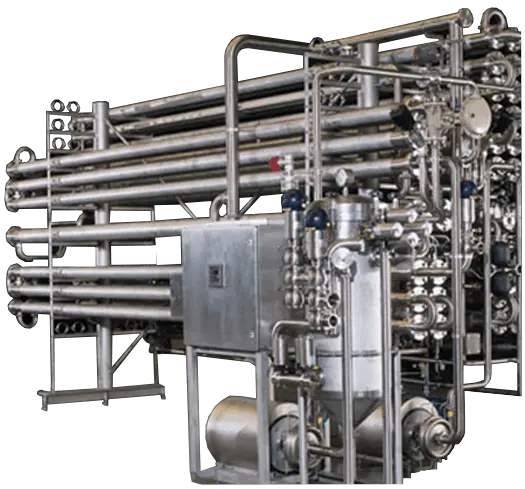

Processing

and Treatment: We offer state-of-the-art pasteurizers,

homogenizers, and separators

that meet the highest standards of safety and performance. Our fermentation

tanks provide the ideal environment for culturing products like yogurt and

cheese, allowing for precise control over the process.

pasteurizer

Product Formation and Packaging:

From butter churns to cheese vats and ice cream freezers, our equipment ensures

consistent quality and efficient production of diverse dairy products. We also

provide advanced filling and packaging solutions for various container types,

streamlining the final stages of processing.

Cleaning and Sanitation:

Maintaining hygiene is paramount in dairy

processing. Our Clean-in-Place/

CIP

systems automate the cleaning process, ensuring thorough sanitation and

preventing contamination.

CIP

Beyond Standard Equipment:

We stay ahead of the curve by

offering advanced technologies such as membrane filtration systems for protein

concentration and separation, and Ultra-High

Temperature/UHT processing

for extended shelf life. Our commitment to innovation ensures that our clients

have access to the latest advancements in dairy processing technology.

UHT

Focus on Efficiency and

Sustainability:

We recognize the importance of

efficient and sustainable practices in today's dairy industry. Our equipment is

designed to minimize energy consumption and waste generation, contributing to a

greener future for the sector. We also offer solutions for water and energy

recovery, helping our clients reduce their environmental footprint.

More than just Machines:

At Neologic Engineers, we believe

that equipment is more than just machines; it's the foundation upon which

successful dairy businesses are built. We are passionate about providing our

clients with reliable, efficient, and innovative solutions that empower them to

produce high-quality dairy products while optimizing their operations.

Partner with Neologic Engineers and

let us equip your dairy processing plant for excellence.

This comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDelete